Industrial Visits: Enriching Academic Learning with Practical Wisdom

Industrial visits form an integral part of the experiential learning ecosystem at CIMAGE. Rooted in the belief that real-world exposure substantially enhances classroom understanding, the institution organizes structured industrial tours for students across all streams. CIMAGE offers a dynamic spectrum of programmes including BCA, BBA, B. Com (P), MCA, MBA, B.Sc (IT) and PGDM, empowering students with industry-ready skills and future-focused learning.

Through these visits, students witness how theoretical concepts are translated into practical processes—from manufacturing and automation to IT infrastructure, finance operations, marketing strategies, and workplace management. Companies across diverse sectors such as, manufacturing, medicine, logistics, and FMCG regularly host CIMAGE students and provide guided sessions, demonstrations, and Q&A interactions.

OBJECTIVES OF INDUSTRIAL VISITS

- Bridge classroom learning with real-world practice

- Observe industrial processes and technologies

- Gain practical knowledge and hands-on insights

- Develop industry readiness and professional skills

- Interact with industry experts for guidance

- Strengthen analytical, problem-solving, and observational skills

- Explore potential career paths

BENEFITS OF INDUSTRIAL VISITS TO THE STUDENTS

- Practical Understanding: Students observe how theoretical concepts are applied in real-world situations.

- Industry Exposure: These visits help students familiarize with professional environments, processes, and technologies.

- Skill Development: Visits help enhance the ability of problem-solving, analytical, and observational skills.

- Career Awareness: Explore potential career options and industry roles.

- Professional Networking: Interact with industry experts and gain valuable insights.

- Motivation, Inspiration & Confidence Building: Inspire students to innovate and pursue excellence in their fields while also improving their communication and adaptability.

INDUSTRIAL VISIT: JAIPUR CHAPTER

CIMAGE students embarked on an insightful industrial visit to Jaipur, where they explored some of the city’s most prominent and innovative industries. Their journey included visits to Balaji Industries, Manu Yantralay, Genus Power Infrastructure Limited, and the socially impactful Jaipuria Foot. Through these visits, students gained firsthand exposure to real-time industrial processes, modern manufacturing techniques, power infrastructure systems, and cutting-edge assistive technology—broadening their understanding beyond classroom learning and inspiring them for future careers.

1. BALAJI INDUSTRIES

Students visited Balaji Industries, one of Jaipur’s prominent industrial units, exploring its third and fifth production units. The industry’s director, Mr. Ashish Kanodia, guided the students through the entire manufacturing process, explaining each stage in detail. The visit provided a thorough understanding of industrial operations, production management, and the challenges involved in running large-scale manufacturing units

2. JAIPURIA FOOT

At Jaipuria Foot, students observed the complete process of manufacturing artificial feet. They gained insights into the materials, techniques, and precision required to produce high-quality prosthetic products. The experience highlighted the integration of technology and craftsmanship in medical device manufacturing.

3. MANU YANTRALAY

The visit to Manu Yantralay gave students an in-depth understanding of bearing production—from raw materials to final packaging and marketing. They closely studied the manufacturing processes, quality checks, and operational workflow, and also participated in a Q&A session with the director, gaining practical knowledge about industrial management and strategic decision-making.

4.GENUS POWER INFRASTRUCTURE LTD.

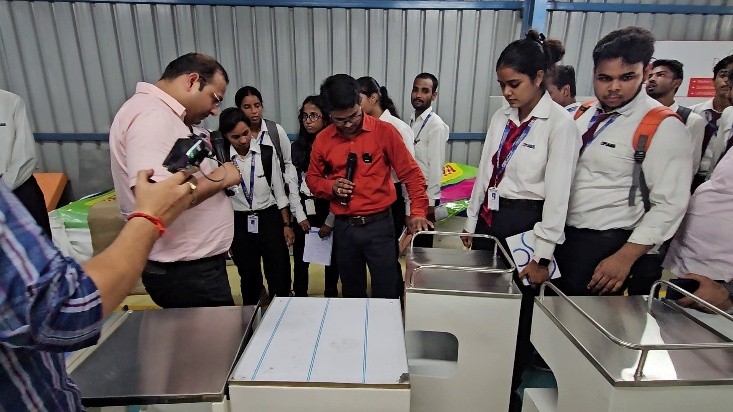

At Genus Power, students explored the manufacturing, processing, and assembly of smart meters. They learned how cutting-edge technology is applied in large-scale production, and gained insights into the operational intricacies, quality control measures, and assembly line management involved in producing smart energy solutions.

JAIN IRRIGATION, JALGAON, MAHARASHTRA

Students visited Jain Irrigation, a leading company in agriculture and drip irrigation solutions. They observed modern agricultural techniques and learned about efficient drip irrigation methods, water management systems, and sustainable farming practices. The visit provided practical insights into how technology is applied to enhance crop yield and resource efficiency, giving students a comprehensive understanding of innovations in the agricultural sector.

INDUSTRIAL VISIT: PATNA CHAPTER

CIMAGE students visited various industries in Patna to gain firsthand exposure to real-world operations. They observed processes, interacted with professionals, and understood how classroom concepts are applied in practice. The visits helped students develop practical knowledge, professional skills, and insight into potential career paths.

1. COCA COLA FACTORY, PATNA

CIMAGE students had the exciting opportunity to visit the Coca-Cola plant, where they witnessed the entire production process, from bottling to quality control. The visit provided a behind-the-scenes look at how a global brand maintains efficiency, hygiene, and consistency on a large scale. Students also interacted with plant engineers and managers, gaining insights into supply chain operations, automated systems, and industry best practices.

2. SHIVA POLYTUBE, FATUHA

Students visited Shiva Polytube, where they gained firsthand insight into the process of pipe manufacturing. During the visit, they observed the production techniques, and learned how the business overcame challenges to grow successfully. Interacting with the owner provided students valuable lessons in entrepreneurship, problem-solving, and industry management, making the experience both educational and inspiring.

3. TEJAS IRON & STEEL PVT. LTD.

Students visited one of the largest steel plants in India, to gain a firsthand understanding of the steel manufacturing process. They observed how raw materials are transformed into high-quality steel through advanced machinery and precision techniques. The visit provided insights into production planning, quality control, and operational management in a large-scale industrial setting.

4. WILLSON MEDICAL SYSTEM PVT. LTD.

Students visited Willson Medical Pvt. Ltd., one of the leading manufacturers of surgical equipment. They observed the production processes closely and understood the precision, technology, and hygiene standards required in the medical manufacturing industry. The visit provided valuable insights into how a large-scale medical unit operates and the challenges involved in maintaining quality and efficiency.

5. SHYAM KRIPA LLP

At Shyam Kripa LLP, Bihar’s first and largest BOPP manufacturing plant, students witnessed how high-quality packaging materials are produced for major clients such as Pepsi, Sudha Dairy, and Britannia. They learned about large-scale production techniques, quality assurance, and the strategies the company uses to meet industrial demands efficiently, gaining exposure to a critical segment of the packaging industry.

6. CENTURY POLYPLAST INDUSTRIES

The visit to Century Polyplast Industries showcased the company’s journey from producing household plastic items to becoming the Bihar distributor for a reputed Bombay-based plastic firm. Students explored the processes involved in manufacturing and distribution, and understood how businesses adapt, expand, and manage operations in evolving markets.

INDUSTRIAL VISIT: HAJIPUR CHAPTER

1. COMPETENCE EXPORTS PVT. LTD.

Students visited Competence Exports Pvt. Ltd., a prominent shoe manufacturing and export company. They observed the complete production process, from designing and assembly to quality checks and packaging. The visit provided students with practical insights into the footwear industry, along with valuable knowledge about international trade and export operations.

2. AFP MANUFACTURING COMPANY

At AFP Manufacturing Company, students explored the production of Kurkure snacks. They visited the entire production unit, learning about the manufacturing techniques, machinery, and quality control measures that ensure consistent product standards. The experience gave students an understanding of large-scale food processing and operational management.

3. GREEN POLYTUBE COMPANY

The visit to Green Polytube Company allowed students to observe the manufacturing and production of pipes. They gained insights into the different stages of production, the technologies involved, and the operational challenges faced in the plastic industry, enhancing their practical understanding of industrial processes.

4. SOBISCO BISCUITS PVT. LTD.

At Sobisco Biscuits Pvt. Ltd., students witnessed the complete biscuit production cycle, from preparation and baking to packaging and final dispatch. They learned how efficiency, hygiene, and quality control are maintained throughout the process, gaining a comprehensive understanding of the food manufacturing and packaging industry.

Industrial visits at CIMAGE provide students with invaluable exposure to real-world industries, bridging the gap between classroom learning and practical experience. By observing operations, interacting with professionals, and understanding production and management processes, students enhance their technical knowledge, professional skills, and career readiness.

These experiences inspire curiosity, critical thinking, and innovation, preparing students to excel in their chosen fields. Join us at CIMAGE and be a part of these transformative learning experiences that shape not just careers, but the future of industry-ready professionals